After speaking with Ben I had this beast delivered Friday. Wow what a difference.

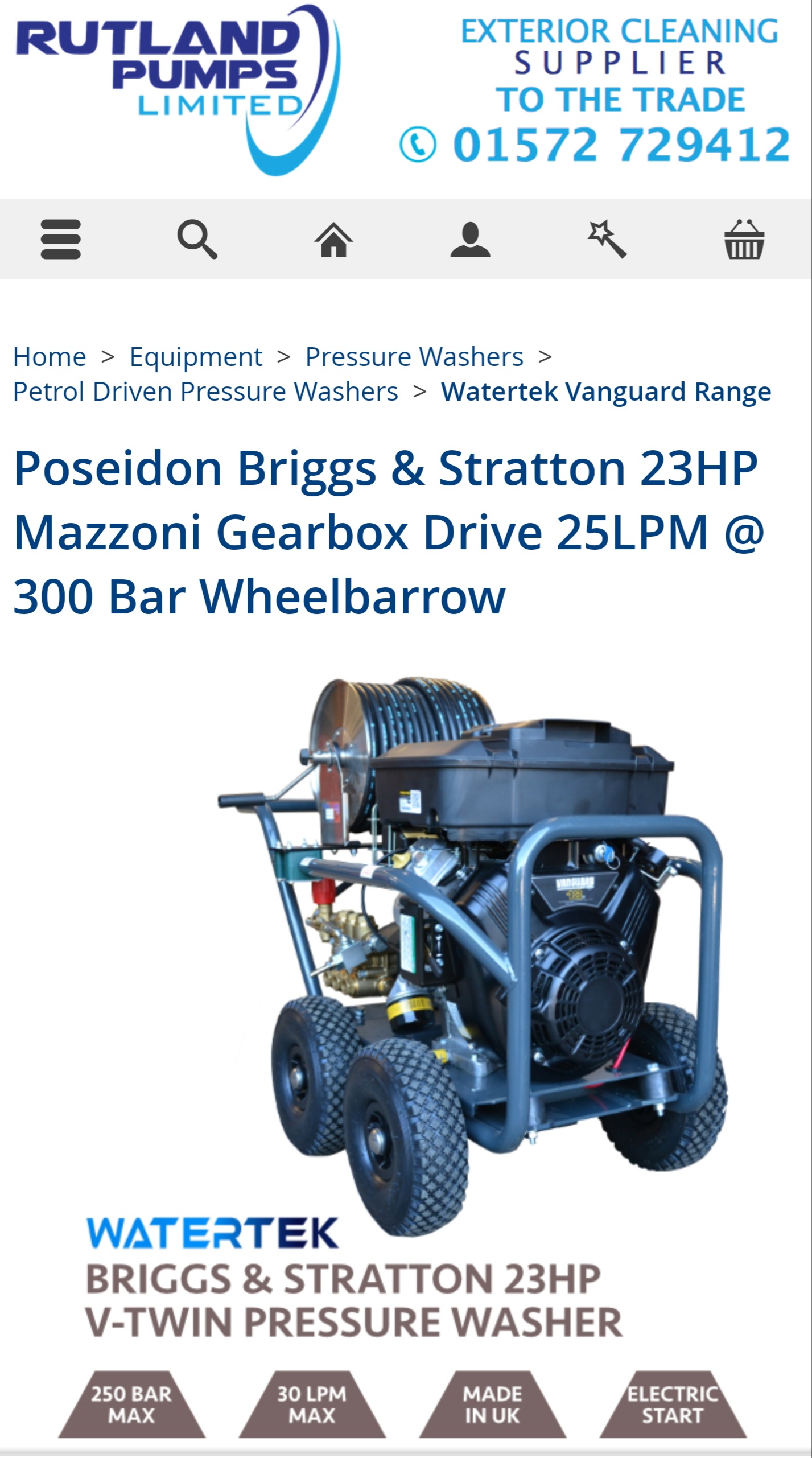

So a like for like - this is the machine that Darren bought and there was a recent thread on it. Great looking machine, should last the lifetime of your business (if looked after, oils changed, serviced, new filters, don't let it run dry).

This does not come with the hose reel as standard - it is an optional extra and also hoses, lances, nozzles will be extra but so are mine.

None of the pricing on their site is out of the ordinary.

My preference is for longer hoses because I work much further away from the van and I pay similar for all parts.

Comparison to mine - 36HP, 200 bar, 3000 psi @ 41 LPM against 23 HP, 300bar @ 25LPM - this becomes the minefield that people don't understand.

36/25 HP is just the amount of grunt the engine has to power the pump, 200/300 bar/psi is the amount of force the surface is hit with by the water flow from the pump and the flow 41/25 is the amount of water that goes alongside the bar/PSI.

All in all they are a very similar side by side machine - if I had any intention of staying in pressure washing and or my machine failed me in the next however long that would be a definite contender.

Petrol will always be more to run than diesel engines, the lads will tell you but somewhere around £12/15.00 per day? as opposed to a fiver per day.

Diesel pressure washers are always a lot more expensive to buy. If you want a Deutz engine substantially more to buy.

What water tank are you having - IBC tank - plenty of space required in the van once the machine and extras are in with it.

I don't like the idea of wheelie bins sat on someones drive. The tank is your buffer against what is going in to what is doing the cleaning.

If you are operating on residential then an average supply may be at best 20 LPM, through a 15 mm hose but could be much lower.

Operating fully commercial hydrants are hired and through a 22mm hose a fill can be as quick as 20 minutes but there are additional costs to hiring hydrants, finding one near the works and the possibility you may need to drive to get the fill.

If you are on constant fill ( a residential) at 20 LPM but are using 25 LPM you need to get onto water as quickly as you get there, start setting your stuff out, which shouldn't be long, because it's just hoses out and connect lance, let say 500 litres of water into the tank, your buffer and start work, eventually you will drain the tank but only at 5LPM and may finish the job without having to stop.

Exhausting the machine. it can come out of the side door, rear doors, through the floor and or a chimney through the roof.

On mine I had a stainless steel exhaust manufactured and it goes out of the back door.

You can use flexi exhaust and put it through the floor but whatever exhaust you use wrap it in exhaust wrap because it bloody burns when (not if) you catch your leg/arm or hand!

Lances for me are not standard.

A typical lance will be trigger with QR connector to the hose, mine are, then lance fixed to the trigger, mine are quick release bayonet fittings. This allows me to change lances without turning the machine off, even FSC, then down the lance a fixed nozzle, so you may need one set up with a turbo and one for flat.

Mine are split flow, so two adjustable pieces of lance tubing with a small tap that allows flow down both lances to rinse at reduced pressure, then onto another QR to insert flat or turbo nozzles.

Hopefully explanatory but if you have further questions get them posted.