I'm going to jump in with both feet.

Does anyone have experience on how an Ionics Diesel heater works. This is with reference to bleeding excess heat generated in the heating water circuit and not used for cleaning when switching the water off.

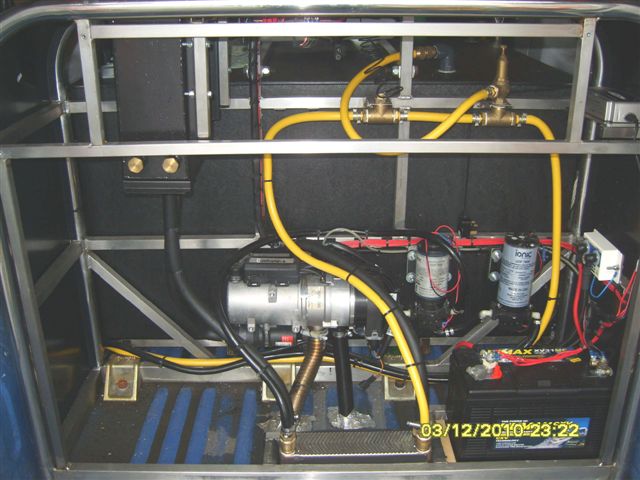

This Ionics unit appears to be a single operator unit as it only has one heat exchanger. It has 2 pumps in series; the right one joining to the second pump. In the top right hand side is a brass t piece with what appears to be a pressure relief valve. It looks similar to a pressure relief valve used in the food industry to release excess hot water/steam. It has a hose leaving from it to the top of the tank - a heat bleed off?

Further to the right is another brass T which looks to have a temperature probe fixed in it.

My guess is that the first pump is your everyday working pump that delivers water to the brush through the second pump and heat exchanger. In my experience we need no more that 60 psi to deliver all the water we need to the brush head. If that temperature probe is connected to a temperature controller it would be easy to activate that second pump. If that pressure relief valve was set at say 70 psi and the second pump to cut off at 100 psi, then that second pump would blow off the relief valve to push all that extra excess heat back into the tank.

But I could be wrong. Help needed.